Rotary Screw Compressor

Rotary Screw Compressor

Variable Speed Drive Compressor (PM VSD Series)

Screw Compressors with permanent magnetic motor TEFC, IP55

SRange from 7.5kW-75kW

Key Features

- Energy saving up to 50% that reduces production cost

- Permanent magnet variable frequency control with a wide adjustment range

- IP55 electrical motor protection from dust and water

- Durable compression module, stable and reliable

- Adopts specialized oil seal with high efficientand no wear

- Eco friendly silent with improved technologyand reliable performance

- Strong adaptability in harsh environments, achoice of all industrial applications

- Flexible coupling direct driven ensures directconnection without loss of transmissionefficiency

- Unique heat removal and cooling systemeffectively increases the heat dissipation arearun faster and smoother

- Less maintenance and operating cost

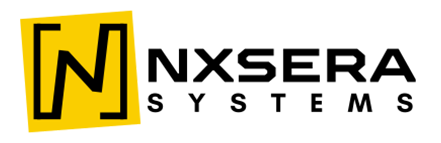

Specifications

Fixed Speed Drive Compressor (FX DD Series)

Key Features

- High performance fixed speed direct drive withless wearing parts and high reliability adjustment range

- IP55 electrical motor protection from dust and water

- Durable compression module, stable and reliable Adopts specialized oil seal with high efficient and no wear

- Eco friendly silent with improved technology and reliable performance

- Strong adaptability in harsh environments, achoice of all industrial applications

- Flexible coupling direct driven ensures directconnection without loss of transmission efficiency.

- Unique heat removal and cooling system effectively increases the heat dissipation area run faster and smoother.

- Less maintenance and operating cost

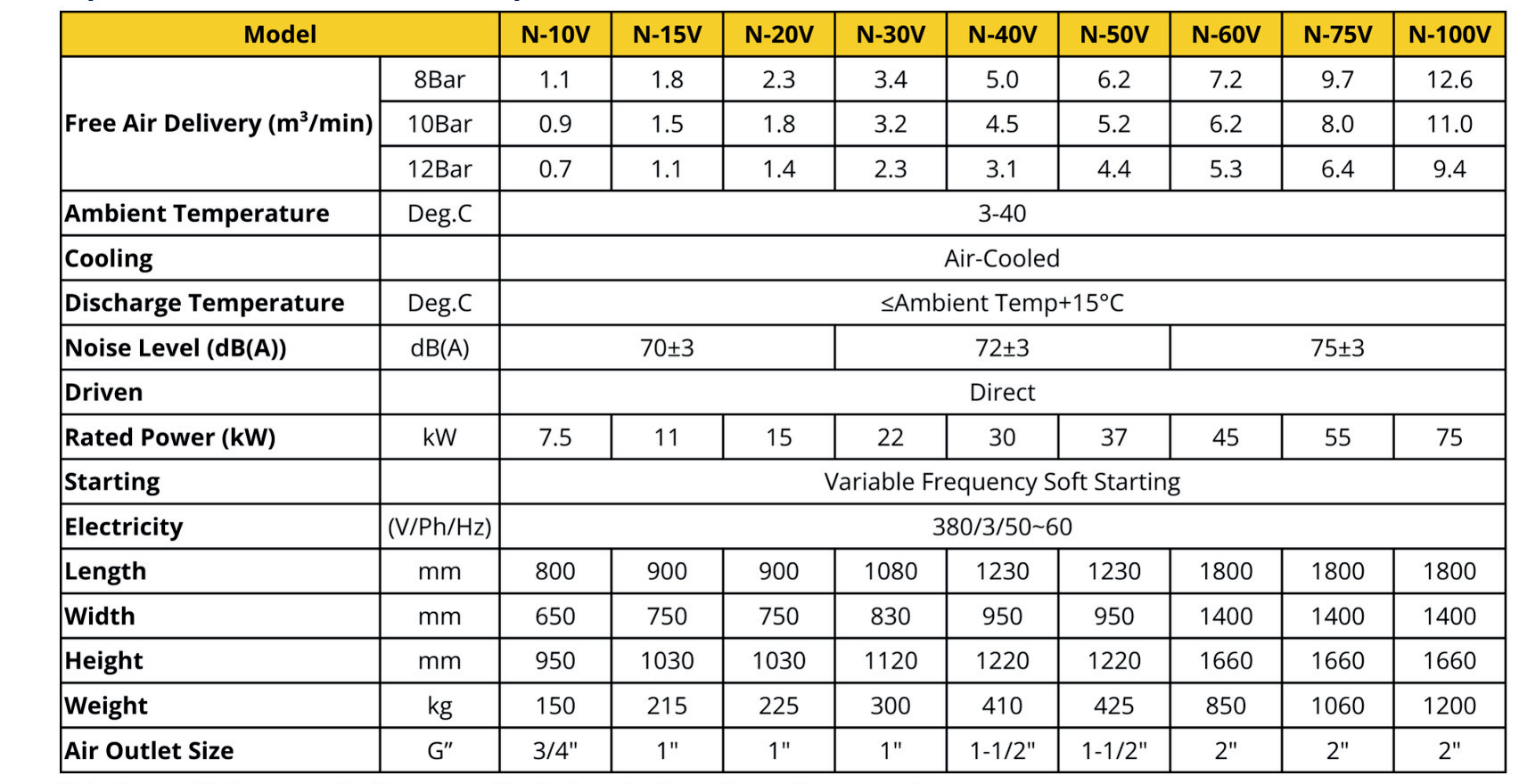

Specification

Tank Mounted Integrated Compressor (ITMD series)

Key Features

- Integrated Screw compressor, Air Dryer, horizontalair receiver and line filters

- Easy to install and less floor area

- Integration choice available in both fixed speed drive and variable speed drive

- High performance fixed speed direct drive with less wearing parts and high reliability adjustment range

- IP55 electrical motor protection from dust andwater Durable compression module, stable and reliable

- Adopts specialized oil seal with high efficient and no wear

- Strong adaptability in harsh environments, a choice of all industrial applications

- Flexible coupling direct driven ensures direct connection without loss of transmission efficiency.

- Unique heat removal and cooling system effectivelyincreases the heat dissipation area run faster and smoother.

- Less maintenance and operating cost

Why Choose A 4-In-1 Air Compressor?

Key Features

- Integrated design with beautiful appearance, fewer parts, and connectors reduce the possibility of unit failureand leakage; direct discharge of dry compressed air, fully guarantee the quality of user terminal gas; greatly savecustomer installation costs and use space.

- With new modular design structure, compact layout, ready to install and work.

- After strict testing of the unit, the vibration value of the unit is far lower than the international standard.

- The integrated and optimized pipeline design reduces the length and number of pipelines, thereby reducing theincidence of pipeline leakage and internal losses caused by the pipeline system.

- Adopting a freeze dryer with excellent performance, a compact rotary refrigeration compressor, and a highcooling capacity configuration scheme to ensure reliable operation under high-temperature conditions.

Single Stage Oil Injection Air Compressor

Key Features

- 1.New generation single-stage screw airend.

- Adopts top quality third generation asymmetric wire twin screw air end designed for higher efficiency by 5%-15%compared to second generation air end. Optimized flow channel design with large rotor with Swedish SKF heavyduty bearings and double lip shaft seal.

- 2.High-efficiency permanent magnetic motor

- It features a larger service factor for varying speeds in air applications, optimizing torque and efficiency to handledifferent loading conditions.

- 3.Intake valve control system

- The specialized design of integrated air intake valve with adjustment range from 0 to 100%, target to reducepressure loss and make longer working life.

- 4.Advanced control technology for PM motor driver

- The motor driver with variable frequency speed regulating rotation system, More energy saving with lower powerconsumption.

- 5.Intelligent microcomputer control system

- Big touch panel for easy operation, optional for multiple languages. The programmable controller is available forexternal remote control to monitor the key functions of air compressor.

- 6.The excellent cooling system

- The fin type heat exchange cooler with 30% surplus to make sure air compressor work perfectly under ambienttemperature 45℃.

- 7.Energy efficient filtration system

- Durable design oil separator tank with larger sized tank volume, having higher precise separation to reduce oilcarryover.

Screw Air End

Simple and robust design which provides high reliability and lowvibration and noise level. Adopts the international top level thirdgeneration asymmetric wire twin screw air end, adheres to theexquisite manufacturing process, adopts the peak high efficiency lowpressure, high efficiency tooth shape and the axial air inlet design.Optimized flow channel design with a large rotor, low speed and highefficiency, increased energy efficiency by 5–15% compared to thesecond generation air end. Built with Swedish SKF heavy duty bearings,double lip shaft seal, durable and reliable. The bearing design life is80,000 to 100,000 hours and the air end design life is about 200,000 hours.

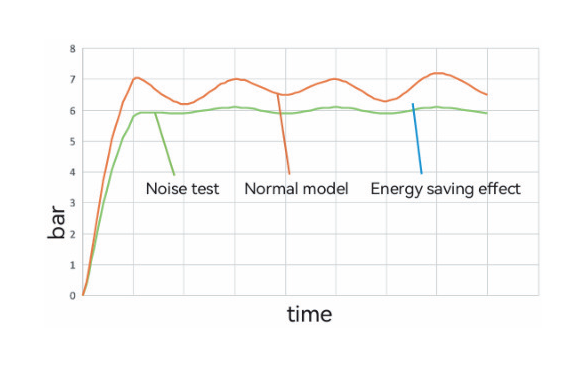

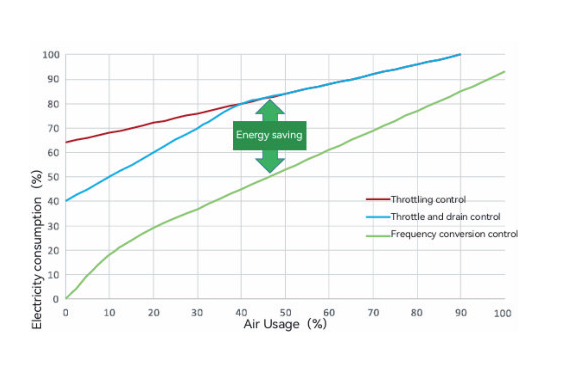

Overall Energy saving

Compared with powered fixed air compressor, variable speed air compressor has practicalsignificance in energy saving.

costThe variable speed air compressoroffers precise pressure control,quickly responding to changes byadjusting the motor's speed. Itmaintains pressure fluctuationswithin ±0.1 bar, stabilizes the pipenetwork's pressure, optimizes airvolume, and minimizes energy loss.

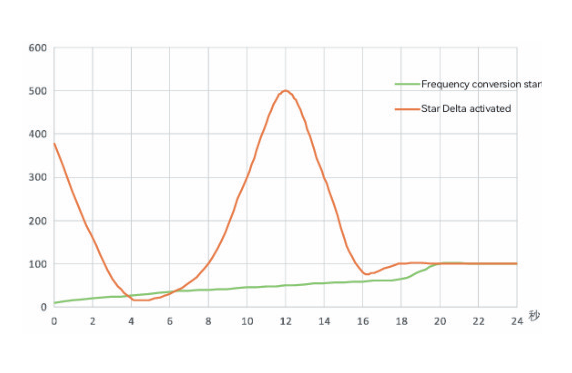

A variable speed air compressoruses frequency conversion forsmooth startup, eliminating peakcurrent from star-delta methods.This reduces starting power,minimizes impact on the power gridand equipment, and lowersoperational noise.

Variable speed control surpassesstandard throttle control, offeringa wider flow rate adjustmentrange. When paired with a high-efficiency permanent magnetmotor, it provides greater energysavings at lower flow rates.

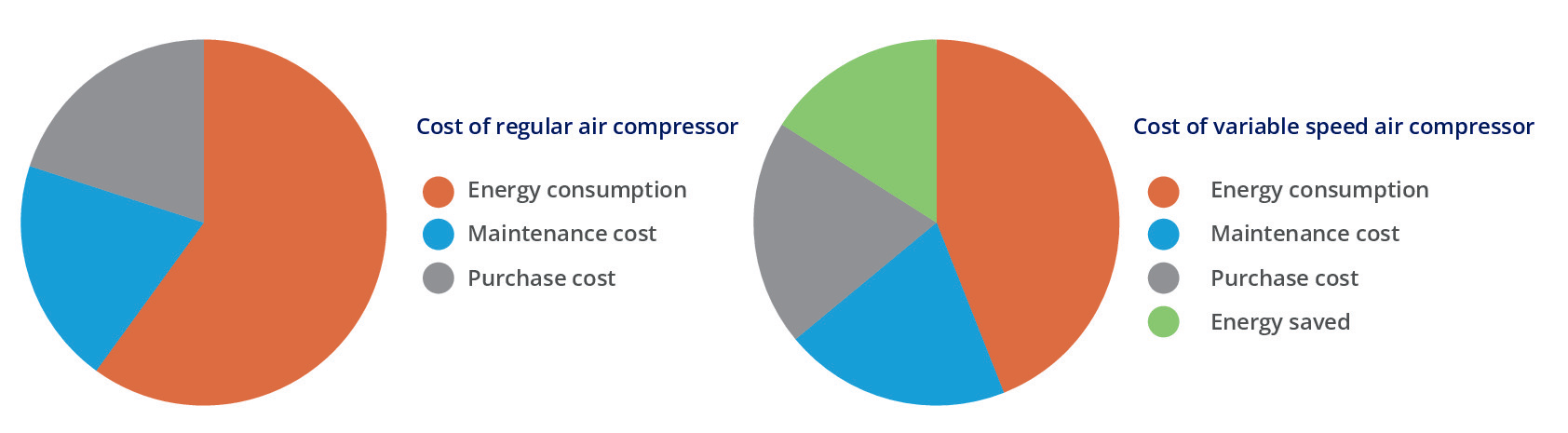

- Most of the cost in the life cycle of the air compressor is generated by the electricity it consumes.

- The power consumption of the compressor is closely related to the on-site air planning.

- The variable speed air compressor can not only ensure smooth production, but also save considerableelectricity costs and achieve a win-win situation for the enterprise.

Using less power to provide more compressedair as well as larger range of air volumeadjustment, 15%-38% savings on electricitycomparing with ordinary constant frequencymachine, and 5%- 10% to ordinary variablefrequency machine. More obvious effect ofenergy saving where the greater fluctuation ofair use.

- High efficiency PM motor saves energy 6–7% comparing with common 3-phaseasynchronous motor.

- Adopts latest air end and 1-shaft structurefor more compact, stable and efficiency.

- Use intelligent inverter technology, PM VFcompressor saves energy up to 30%.

- Owns numbers of patented technologies.

- Industrial LOT functionality.

Complete System

- Removes the condensate that is collected after the air cools in the after cooler

- Removes the condensate that is collected when the air cools inside of the receiver tank.

- Removes the condensate that is collected in the filter bowl.

- Removes the condensate that is collected in the air dryer and filter bowl.